| 1 |

Definition |

Construction on Site |

Manufactured in Factory, Erection on site |

Manufactured in Factory, Erection on site |

Manufactured in Factory, Erection on site (Primarily Steel Buildings) |

| 2 |

Casting |

Casting in open environment, elements can not manufactured in advance |

Elements are manufactured in factory environment in 2D dimensions. Casted in advance |

Elements are manufactured in factory environment in 3D dimensions. Casted in advance |

Column, Beams and roof is made of steel in factory environment. Erected at site |

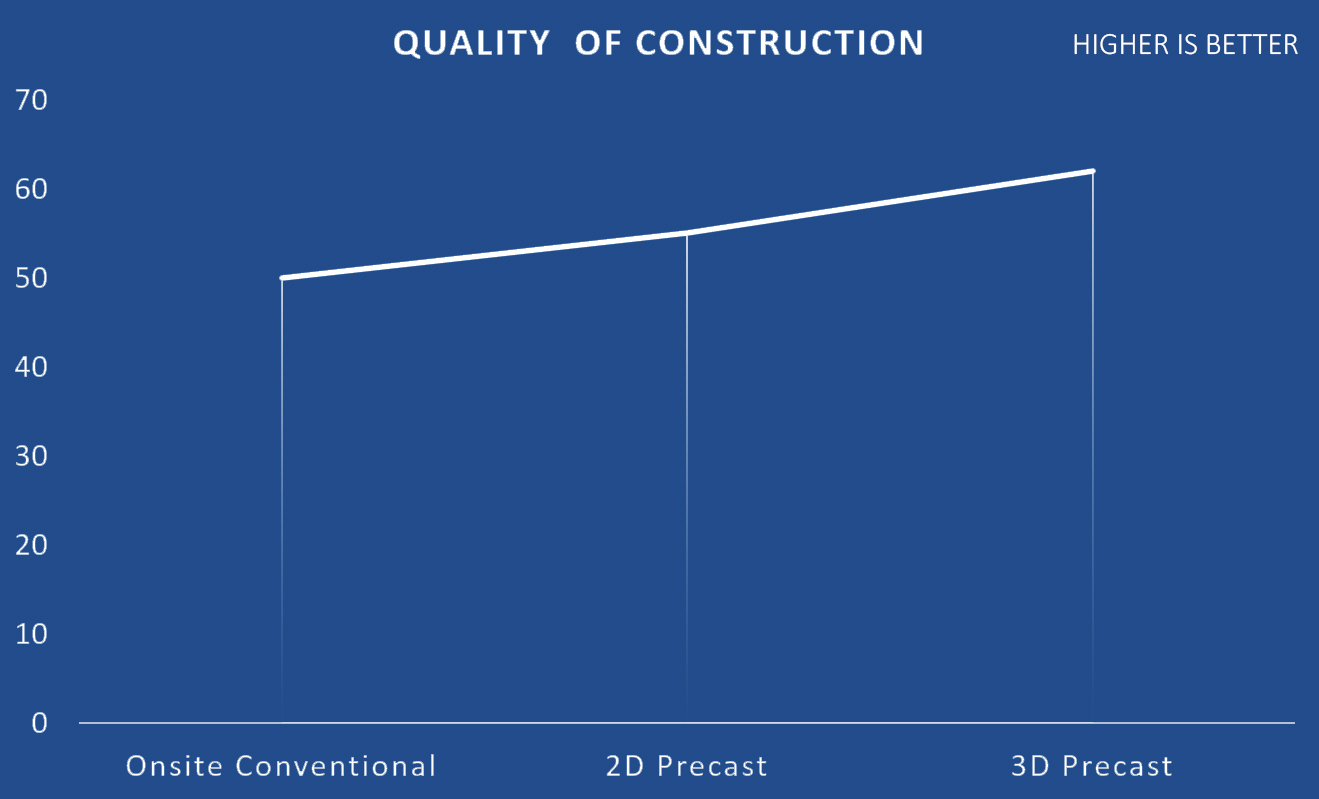

| 3 |

QA/QC |

Very Difficult |

Easily monitoring QA/QC |

Easily monitoring QA/QC |

Easily monitoring QA/QC |

| 4 |

Flexibility |

Last minute changes are possible |

All the planning to made in advance but flexibility is design is possible |

All the planning to made in advance |

All the planning to made in advance |

| 5 |

Labour |

Labour oriented |

Required lesser but skilled resources |

Least requirement of labour |

Labour oriented |

| 6 |

Machines / Equipment |

Least dependent on equipment |

Equipment and machine play key role |

Equipment and machine play key role |

Equipment and machine play key role |

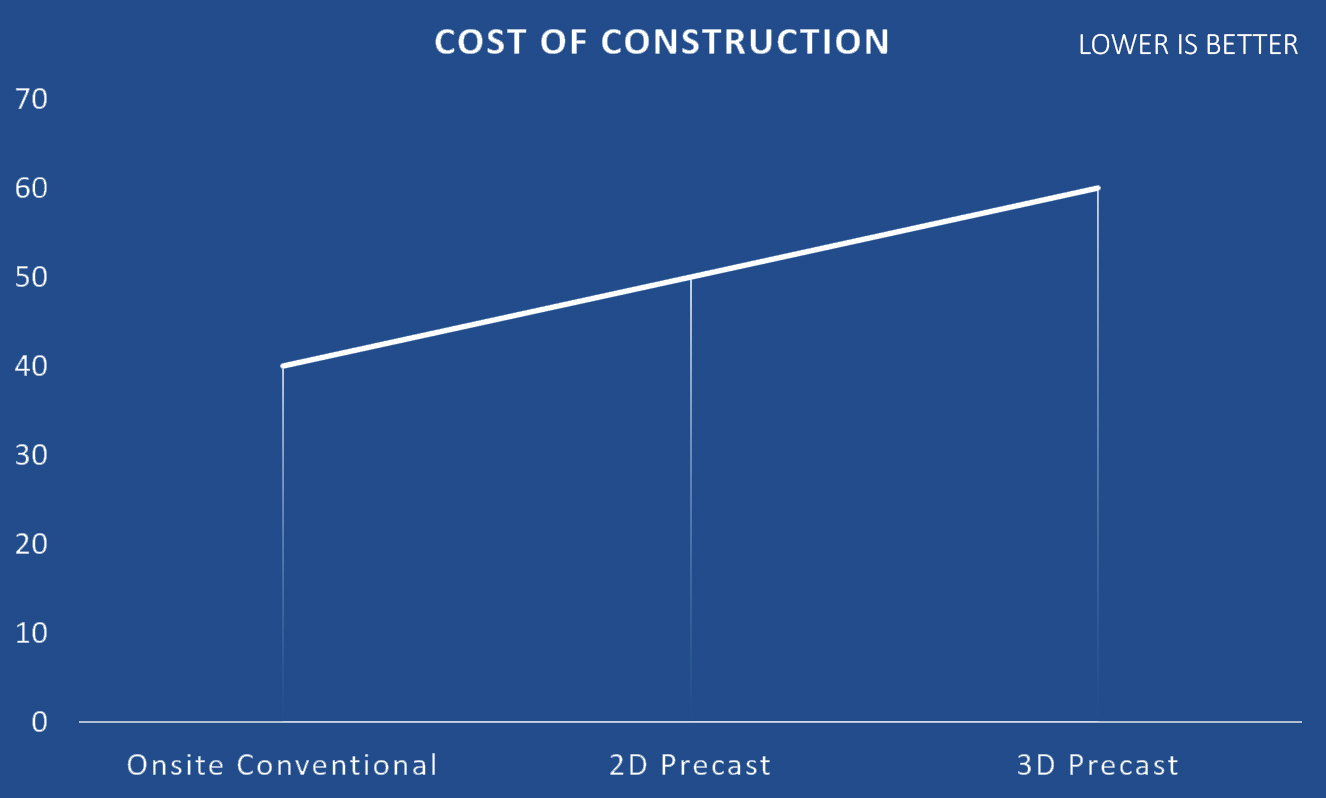

| 7 |

Costing |

Economic initially but expensive in long term |

Comparative with CIS |

10-15% expensive than 2D Precast |

Expensive |

| 8 |

Tracking and Monitoring |

Difficult |

Easily monitoring |

Easily monitoring |

Difficult |

| 9 |

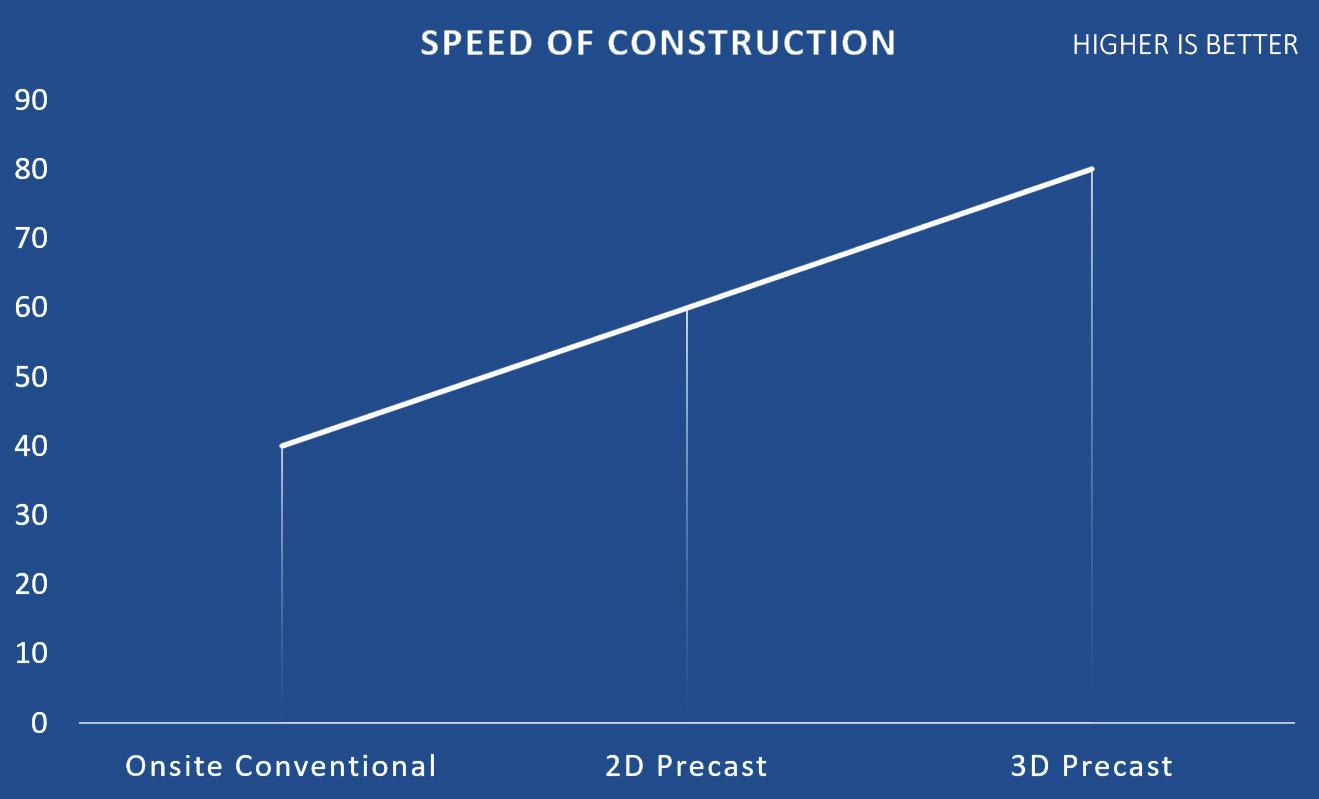

Project Completion |

Mostly Delay due to various reasons like labor, weather local issues |

Project can be completed in half of its time compared to CIS |

Time saving approach. Even faster than 2D precast |

In PEB projects, there is huge amount of CIS work which slow down the speed of construction |

| 10 |

Initial Investment |

No Special investment required |

Investment for precast plant or purchase elements from precast factories |

Investment for precast plant or purchase elements from precast factories |

PEB Elements to procured from PEB suppliers |

| 11 |

Application |

All types of buildings |

Best for long span spans, commercial and industrial projects |

Best for residential projects |

Mainly used for industrial sheds |

| 12 |

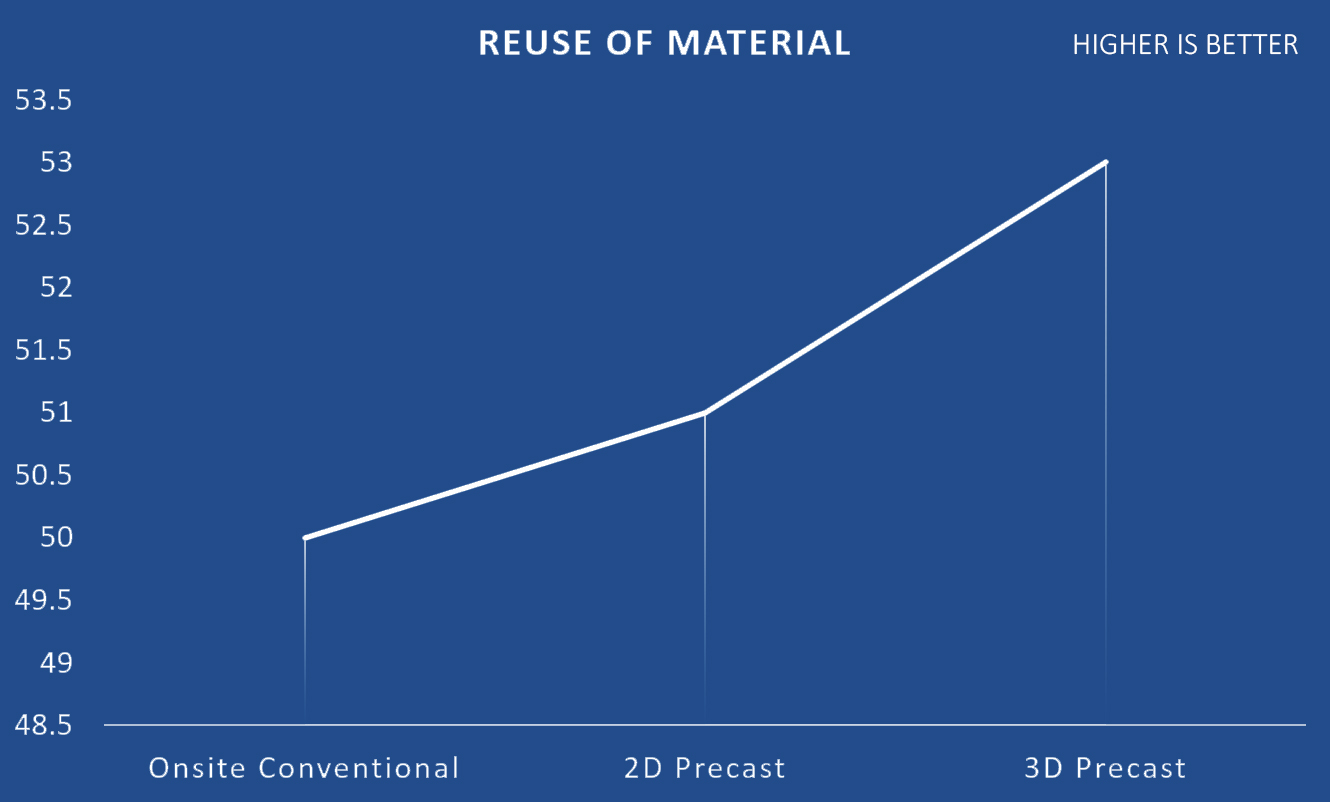

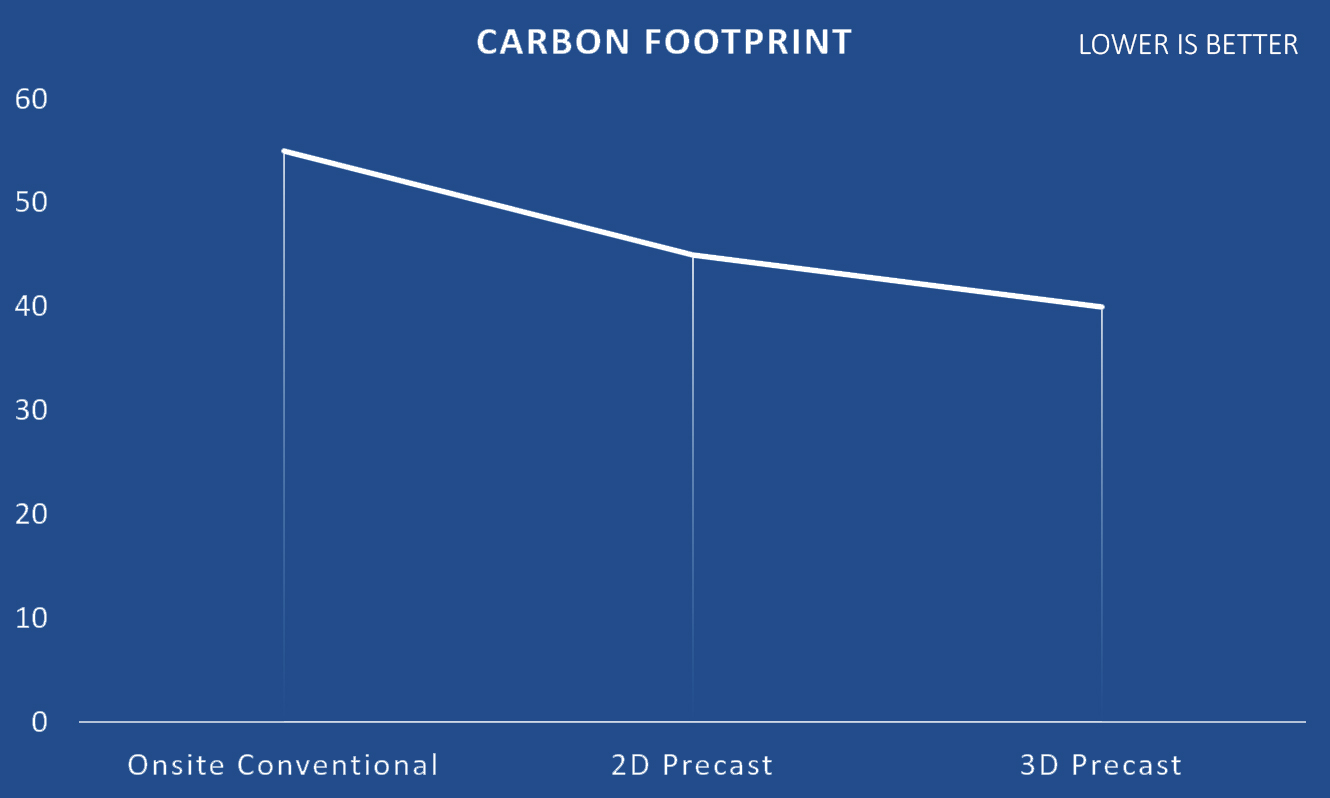

Carbon Footprint |

High as all raw material transported to site |

Low as transportation of raw material is reduced and no form work needed onsite |

Low as transportation of raw material is reduced and no form work needed onsite |

Moderate as steel itself has high carbon value |

| 13 |

Quality of work |

Depended on workmanship of labour |

High quality of work |

High quality of work |

Moderate quality of work |

| 14 |

Duration / Timeline |

More time compare to other technology |

Less time compare to CIS |

Less time compare to CIS and 2D precast |

Less time compare to CIS |

| 15 |

Summary |

Conventional approach, labor oriented, resulted in project delay. It makes it expensive method. |

Upcoming technology which required less labor and more planning. If projects are planned properly, it is economic, time saving and flexible construction methodology |

3D Precast produce complete room and require least work at the site. Helps in project completion on time. Less connections CIS work. Good for remote areas, harsh environmental areas and less populated regions |

If PEB elements are merged with 2D Precast(Column beam in steel, façade and rood with precast), it will be good combination. It will be economical and stronger buildings. |